Composites (i.e. fibre reinforced plastics) are an attractive materials choice for designers, as they combine high modulus materials with freedom of form, resulting in lightweight mechanical structures. Lightweighting reduces resources needed to make the product and energy usage over its lifetime, especially in transport applications. However, mixing fibre reinforcements into polymers causes problems with recycling, in particular for thermoset-based composites.

Composites owe their characteristics to the combination of design, manufacturing and choice of materials. This added value of design and manufacturing is typically lost in a recycling process, it therefore makes economic sense to focus on product and component level strategies to keep the material longer in the system.

In my PhD project I develop design strategies for products containing composite materials in a Circular Economy. The project is embedded in Horizon2020 project Ecobulk, a large scale demonstration effort to close the loop for composites.

This page lists the published results of this research project.

Circular Composites

Circular Composites: A design guide for products containing composite materials in a circular economy Composites…

Design method testing

Circular Composites by Design: Testing a Design Method in Industry The design of composite products…

Circular design framework

Circular Design of Composite Products: A Framework Based on Insights from Literature and Industry Composite…

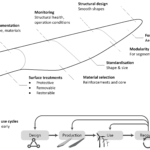

Structural reuse through segmentation

Composite materials offer many advantages during the use phase, but recovery at the end of…

Structural reuse: design case study

How to design a composite product to facilitate structural reuse? Structurally reusing parts of end-of-life…

Offshore wind farm decommissioning

A significant part of wind energy in the Netherlands is generated by offshore wind farms…

Ecobulk progress reports

Project Ecobuk aims to demonstrate a Circular Economy for products containing composite materials. Together with…

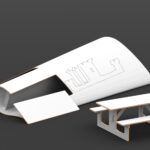

Blade table

Much of the value of composites is in their composition; attempts to separate the fibres…

Slotted Bench

This bench preserves the composite material’s structural value by cutting panels directly from a used…